Fish Feed Extruder Machine IntroductionA floating fish feed extruder is a machine used in aquaculture to produce high-quality feed pellets for fish and other aquatic animals. It is designed to produce feed pellets with various of size, shape, and nutritional content, which can improve the growth, health, and overall quality of the fish.

As we all know, Diesel engine fish feed extruder machine using for aquaculture and animal feed pellets making. For example: floating fish feed(Catfish,Tropical fish)、shrimp feed, Crab feed, dog /cat pet feed,tortoises, frogs and so on. Just change feed machine mould,can make many different shape pellets. also can make different size from 0.4mm-15mm , can feed from baby fish to big fish.

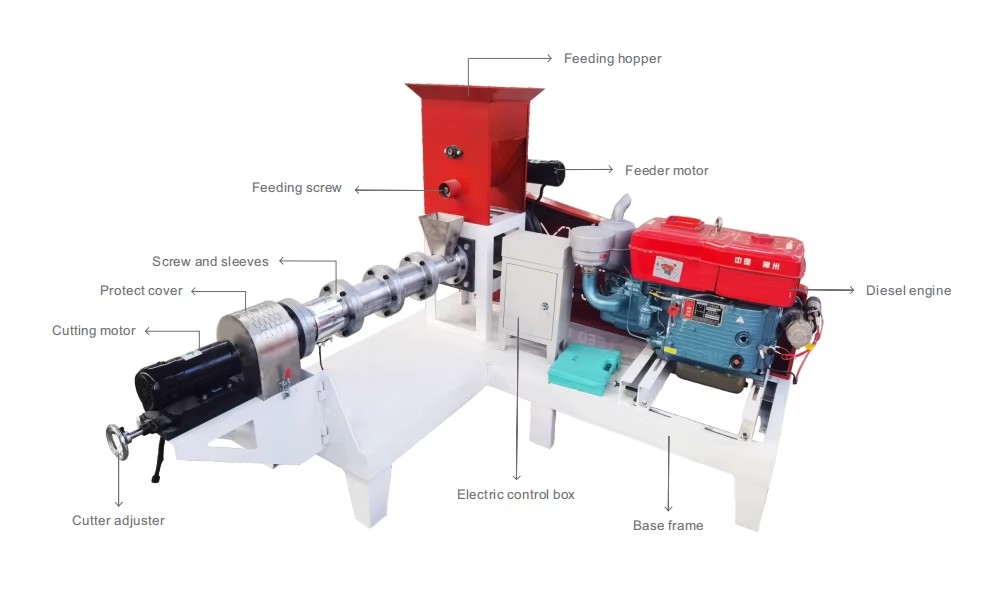

The main parts of fish feed extruder is screw and die.The process of extrusion involves cooking and compressing the raw materials under high pressure and temperature to create pellets with a desired density and texture. The feed extruder has a screw inside a barrel that rotates and pushes the raw materials forward while subjecting them to heat and pressure.

A diesel engine fish feed extruder is a type of fish feed extruder that is powered by a diesel engine instead of electricity. This type of extruder is particularly useful in areas where electricity supply may be unreliable or unavailable, such as rural or remote locations.

The basic principle of operation for a diesel engine fish feed extruder is similar to that of an electrically powered extruder. It still uses the process of extrusion to produce fish feed pellets from a mixture of ingredients. However, instead of being powered by an electric motor, the extruder is equipped with a diesel engine that drives the machinery

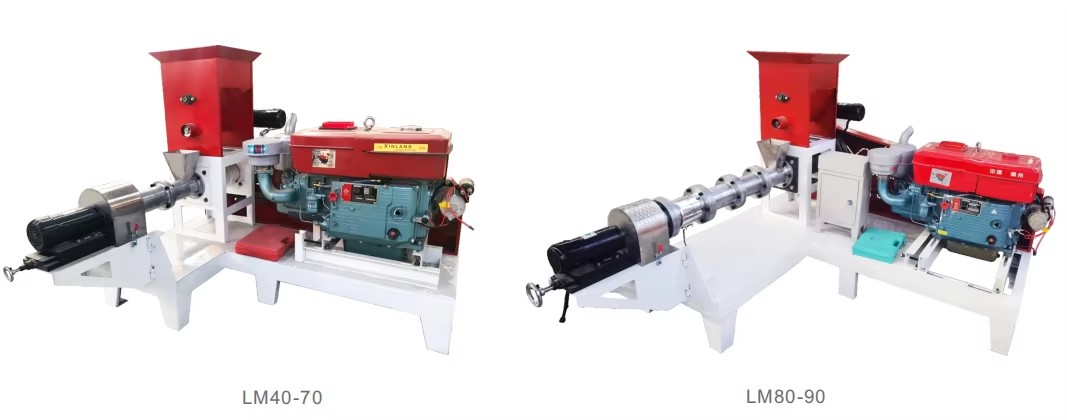

Lima Feed Machinery is professional feed machinery manufacturer, we produce machines of various models and specifications. The following are the model details of common electric fish feed machines. More model, contact our online service!

| Model | Capacity (kg/h) | Main motor (kw) | Feeder motor (kw) | Screw diameter (mm) | Cutter motor (kw) | Machine size(mm) | Weight (kg) |

| 401QD | 40-60 | 5.5 | 0.4 | Φ40 | 0.4 | 1400×1030×1200 | 240 |

| 401BS | 40-60 | 5.5 | 0.4 | Φ40 | 0.4 | 1400×1030×1200 | 280 |

| 401QS | 40-60 | 5.5 | 0.37 | Φ40 | 0.37 | 1400×1030×1200 | 280 |

| 501BS | 80-100 | 11 | 0.4 | Φ50 | 0.37 | 1470×1100×1250 | 340 |

| 501QS | 80-100 | 11 | 0.37 | Φ50 | 0.4 | 1470×1100×1250 | 340 |

| 601BS | 160-180 | 15 | 0.4 | Φ60 | 0.4 | 1470×1100×1250 | 450 |

| 601QS | 160-180 | 15 | 0.37 | Φ60 | 0.37 | 1470×1100×1250 | 450 |

| 701BS | 180-200 | 18.5 | 0.4 | Φ70 | 0.4 | 1650×1400×1300 | 480 |

| 701QS | 180-200 | 18.5 | 0.37 | Φ70 | 0.37 | 1650×1400×1300 | 480 |

| 801BS | 200-300 | 22 | 0.6 | Φ80 | 0.6 | 1800×1450×1300 | 760 |

| 801QS | 200-300 | 22 | 0.55 | Φ80 | 0.55 | 1800×1450×1300 | 760 |

A Electric Engine Fish Feed Machine is powered by electric engines, The electric engine powers the various components of the machine, such as the mixing blades, pelletizing mechanisms. Electric Engine Fish Feed Machine are designed to have multiple functions, including mixing different types of ingredients such as fish meal, grains, vitamins, and minerals, as well as shaping the mixed ingredients into pellets or other forms suitable for feeding fish.

A Diesel Engine Fish Feed Machine is a type of machine that is used to produce fish feed for fish farming or aquaculture

operations. As the name suggests, this feed machine is powered by a diesel engine, which drives the various components of the machine to produce fish feed.The diesel engine fish feed machine is suitable for use in areas where electricity supply is limited or unreliable. It is a rugged and durable machine that can operate in harsh environments and produce high-quality fish feed efficiently and cost-effectively. Fish farmers and aquaculture operators who operate in remote areas or off-grid locations often

prefer diesel engine fish feed machines for their reliability and convenience.

Wet fish feed extruder is a kind of fish feed machinery that needs steam to operate. It is designed for the production of

high-quality fish feed and pet feed with a high fat content and is often used in large-scale industrial fish feed production. A steam boiler is an important part of an industrial fish feed machine as it generates the steam needed to operate the extruder.

Steam is produced by heating water in a boiler to generate high-pressure steam, which is then used to drive the extruder. The Steam Boiler Industrial Fish Feed Machine is capable of producing high-quality fish feed with good texture, high nutritional value and good water stability. It is suitable for the production of feed for various fish species such as tilapia, catfish, trout and carp. It is also suitable for producing pet food such as cats and dogs. This type of fish feed machine is typically used in large-scale industrial fish feed production where large batches and consistent production are required.

Twin Screws: Two screws work together in the extruder to mix, knead, cook, and shape the fish feed ingredients. High Production

Capacity: The twin screw extruder has a high production capacity, producing large quantities of fish feed in a short amount of time. Easy Operation and Maintenance: The extruder is easy to operate and maintain, with simple controls and easy access for cleaning and maintenance. Energy Efficient: The twin screw fish feed extruder is energy efficient, using less energy to produce a large volume of fish feed compared to other types of fish feed machines. Overall, the Two Screw Fish Feed Extruder is a versatile and efficient machine that is capable of producing high-quality fish feed for fish farming and aquaculture operations.

Factory Machine Display