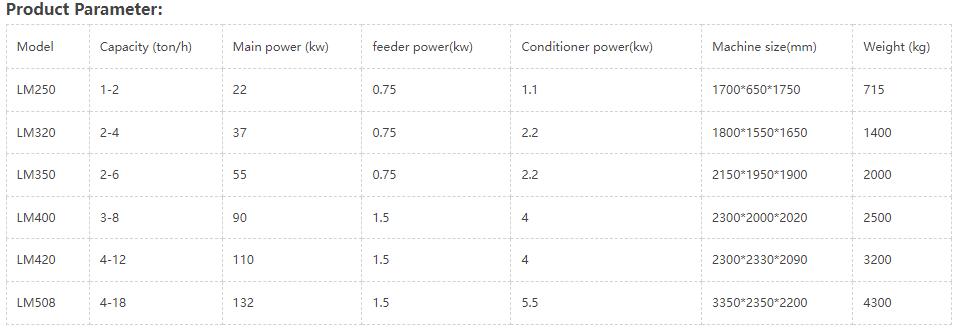

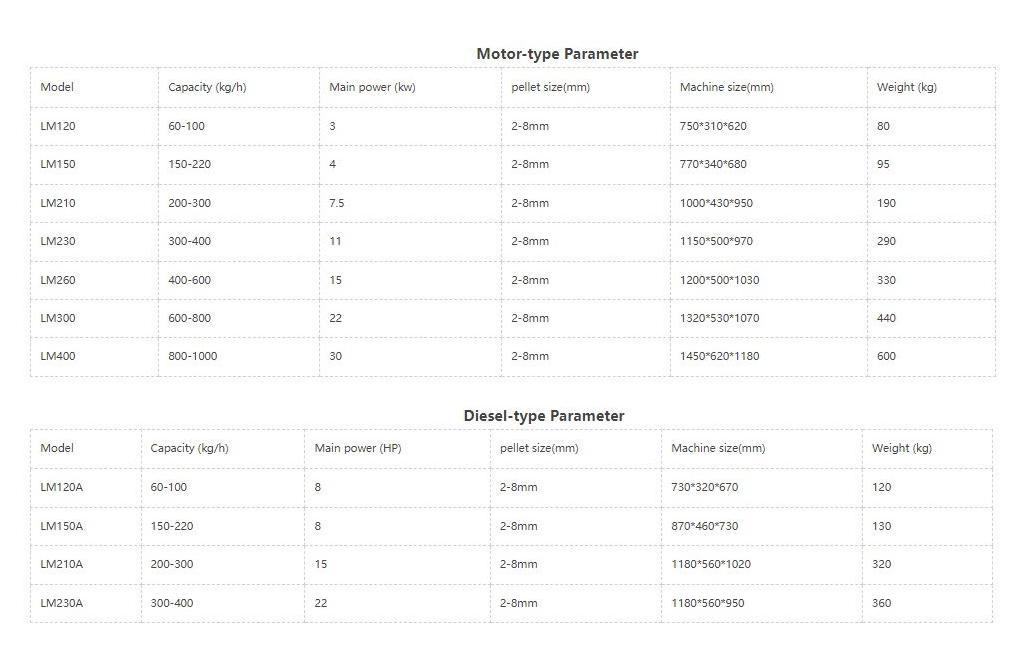

Capacity: 200-300kg/h, 500-600kg/h, 800-1000kg/h,1-20t/h

Pellet Size: 1.5mm-12mm

Application: chicken feed, cattle feed, pig feed, sheep feed

Including crusher-mixer-pellet machines, coolers are the main and important machines of the production line, the extra machines such as conveyors, seasoning machines, and packaging systems depend on clients’ options.

The poultry feed production line is fully complete and automatic poultry feed production line. The complete poultry feed production line includes poultry feed pellet machine, poultry feed crusher, poultry feed mixer, poultry feed cooler, manual type weight, and sealing machine and each part is connected by screw conveyor machines. The poultry feed production line can process corn, soybean, wheat, grains, protein, and other raw materials into pellets with rich nutrition and texture, which are widely used in poultry, cattle, sheep, pig, and other livestock.

This poultry feed production line is the best choice for small and medium feed factories and farms. it has different capacities for customers to choose from large to small. There are 200-300kg/h, 500-600kg/h,800-1000kg/h, 1-20t/h etc.

The raw materials in the crusher are fed into a crusher to be pulverized into powdery raw materials, and then distributed to each batching bin by a conveyor according to the raw material type, so it is a main equipment . Increasing the contact area of digestive enzymes with raw materials, reducing the chewing energy consumption of the animal feeding process, is conducive to improving the feed harvester, and the crushed raw materials are easily matured in the granulation and tempering stage, and the crushed feed can be large in the granulation process. The reduction in power consumption can improve the quality and efficiency of subsequent processes.

The raw materials in the formula are added first, then the trace elements are added, the particle size is increased first, and then the particle size is small, the specific gravity is small, and the addition ratio is large, try to avoid delamination: The reason why the chicken material is easy to stratify) The particle size of each raw material in the mixture is close to each other, and the addition of the oil and fat can reduce the delamination of the raw material. Avoid over-mixing, release the product before the optimal mixing time, in order to complete the mixing during transportation, and add anti-layering equipment to the mixing process to minimize the storage time of the product in the silo.

The mixed powdery feed is processed into pelletized feed. Feed granulation is easy to digest. During the granulation process, the raw materials of the granules must be stirred for a period of time by a suitable amount of water at a high temperature. The raw materials of the granules are ripened and softened and bonded, and the mechanical energy generated during granulation can increase the raw materials. The degree of damage is easier to digest. If the feed is easier to digest, the animal can absorb its nutrients more quickly and the “meat ratio” will be lower. The taste is good . The pellets have a good scent. The granulation process can also spray other materials on the surface of the granules. The taste is better and the nutrients are more uniform: the ingredients in the formula can be mixed together, so that each granule is Stable nutrients can be achieved, animals can not be selected when eating, and the composition of the formula can use a variety of raw materials.

During the granulation process, a large amount of heat is generated due to the introduction of high-temperature, high-humidity steam, and the material is just discharged from the pellet machine, the water content is 16%-18%, and the temperature is as high as 75 C-85C, under these conditions, the pellet feed is easily deformed and broken, and it will also cause sticking and mildew during storage. It must be reduced to below 14% and the temperature is lowered to 8 °C below the temperature. This requires cooling.

This poultry feed pellet machine is used for chicken, cattle, sheep, pig, etc.

1.How about the quality assurance?

Our company has been established for more than ten years. All products have passed CE and ISO9001 quality certificates. We have a professional department to test and adjust machines before shipping for you. We also have certifications in SGS, PC, and SONCAP.

2.How about the warranty?

Our warranty is one year. Our reception is 24 hours on the line talking with you. If the machine has any problems within one year, we offer repair service for free, free accessories, except for man-made damage.

3.Do we need to install the machine?

If you purchase a production line, we will have an engineer come to installation, 100 USD/engineer for one day, typically needs 2-3 engineers. We have operation instructions and videos to guide you if you buy small machines. If you still have problems, we provide professional service and teach you. We make sure your device is working very well 100%.

4.How to pay, payment method?

T/T or L/C at sight. By T/T 40% as down payment, 60% by T/T before delivery.

5.How can I know the status of my order?

We will send you photos and videos of your order at different stages in time and keep you informed of the latest information. We also can give you the shipping company website you can follow any time.

6.How do I use local materials to make the feed you do in your video?

We will provide the formula for free, and we can make the recipe based on your local ingredients, don’t worry about it.

7.Are the parts replaceable?

Parts can be replaced, so you can buy some spare parts when you buy our machine.

8.I don’t know the capacity, how to calculate my capacity?

If you buy ten 25kg bags of feed a day, you need 250kg a day.